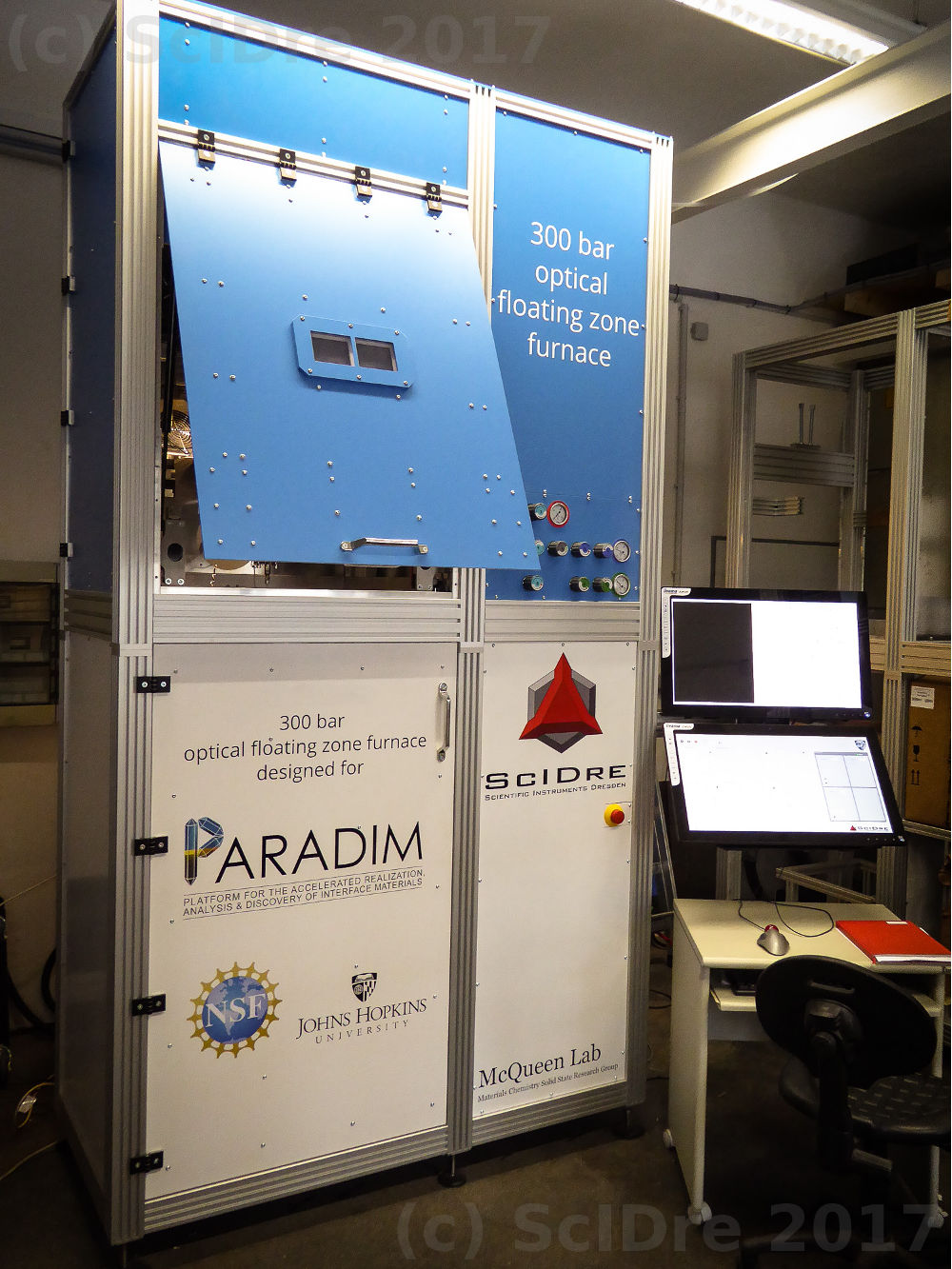

The Dresden-based high-tech company Scientific Instruments Dresden (ScIDre) has succeeded in bringing a unique crystal growth furnace onto the market. The floating zone apparatus is optically heated and enables the growth of high-melting single crystals under gas pressures of up to 300 bar. The composition of the gas mixture is freely selectable by the user. These experimental opportunities give science a completely new parameter range for material synthesis, world-wide for the first time.

The first customer of the latest ScIDre machine is the Johns Hopkins University located in Baltimore, MD, USA, to be housed in the PARADIM Crystal Growth Facility. With the new crystal growth furnace and a number of other innovative products, ScIDre is securing the jobs of the Saxon company since 2009.

Dresden. A major topic of basic materials science is the growth of complex single crystals, which do not exist in nature. The investigation of these new materials contributes to the basic understanding of physical phenomena. However, new crystal systems are also grown because of their properties in various, technically relevant areas like high-performance optics and microelectronics.

With a previous version of the new high-pressure optical floating zone crystal growth furnace (HKZ), ScIDre has been on the market since 2009 and has thus made a name for itself in scientific institutes worldwide. The machine (picture 1) operates according to the so-called optical zone melting method. A small part of a rod-shaped material sample is melted with intense light and the single crystal is grown from the melting zone, while the starting material is continuously fed into the melting zone (picture 2). The required light energy is provided by one powerful xenon short arc lamp and allows melting temperatures of more than 3000 °C. A unique selling point of the HKZ is the option to apply up to 150 bar gas pressure inside the process chamber and to guarantee the required precision of pulling drives at the same time.

Technological world record

Now ScIDre has succeeded in increasing the maximum gas pressure to 300 bar without having to accept losses in the precision of the growth process – a technological world record! Together with the option to freely vary the composition of the gas mixture, a door has been opened to a new world of materials discovery and synthesis.

International cooperation

The development of the new crystal growth furnace was initiated by the Johns Hopkins University. Together with the three well-known universities Cornell, Clark Atlanta and Princeton, Johns Hopkins belongs to the material innovation platform PARADIM (Platform for the Accelerated Realization, Analysis and Discovery of Interface Materials). The goalof the platform funded by NSF (National Science Foundation) with $ 25 million is the synthesis and investigation of new materials, and the study of those materials’ interface properties.

"It is a great pleasure for us," says Robert Schöndube, Managing Director of ScIDre in Dresden, "that we have received the confidence from the top scientists in the USA to develop the 300-bar version of our HKZ." One of them, Prof. Tyrel M. McQueen, co-appointed in the Departments of Chemistry, Materials Science and Engineering, and Physics and Astronomy at Johns Hopkins University, summarizes his motivation to acquire the new plant: "Materials science is the basis for so many technological achievements“, he says. "Our modern world, for instance, is hard to envisage without the materials of microelectronics which are available today. Consequently, still not invented future technologies will also depend on new materials with new properties," says Prof. McQueen. The Associate Director of the PARADIM facility located at Johns Hopkins University, Dr. W. Adam Phelan, mirrors Prof. McQueen sentiments. Phelan states, “This new furnace will allow the PARADIM user base and us to explore materials phase spaces previous unreachable, thereby increasing materials discovery efforts for basic and applied sciences”.

The efficiency of the crystal growth process increases

In addition, the increased pressure increases the efficiency of the crystal growth process. "With the new plant," says McQueen, "an experienced scientist will only need one to three days to grow a pinky-sized crystal. At the moment the whole thing still takes some months. We are also able to process a wide range of different material systems on one and the same machine with the high flexibility of the plant concepts in terms of gas mixing, pressure, light output and pulling speeds."

The new HKZ system was packaged for the trip to the USA last week and will be put into operation by ScIDre employees on 25 February 2017.

About the High-Pressure High-Temperature Optical Floating Zone Furnace (HKZ):

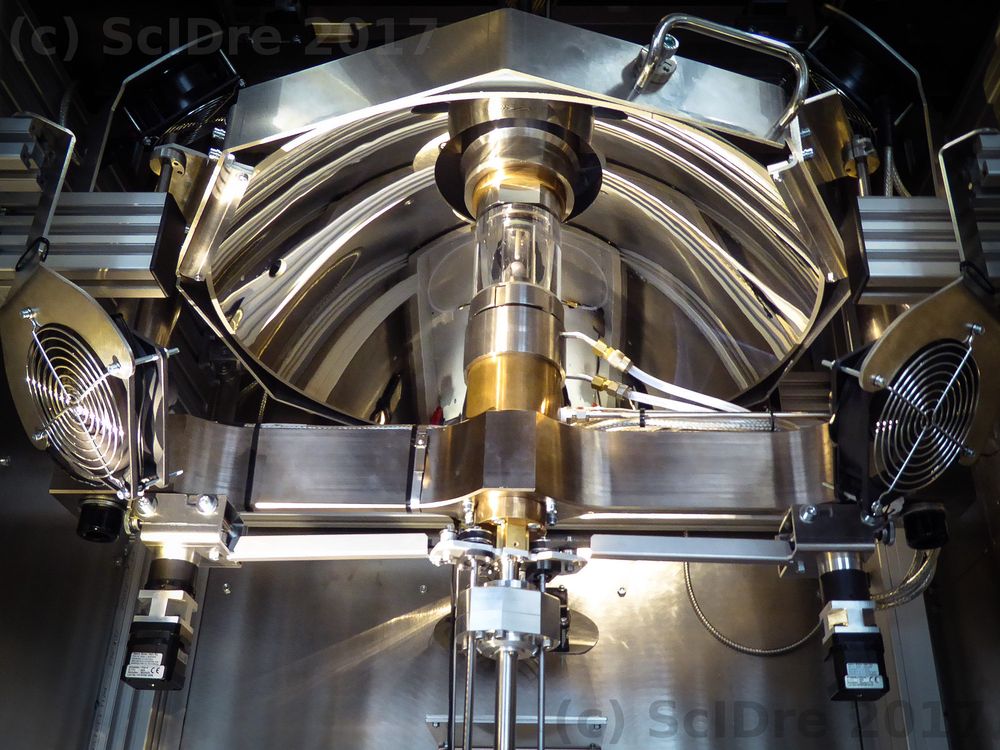

The system has a vertical 2-mirror setup, which allows a homogeneous and very controllable energy distribution on the surface of the material sample. World novelty in this furnace is the possibility of working with different pure and mixed gases in the growth chamber at pressures of up to 300 bar. With one xenon short arc lamp, melting temperatures of more than 3000 °C can be achieved. The growth process can be controlled with magnetically coupled linear and rotary feed systems at pulling speeds from 0.1 mm/h with process monitoring technologies. By means of a non-contacting, patented temperature measuring system, the temperatures of the feed rod, melt zone, and crystal can be measured in situ directly during the growing process. The entire crystal growth machine is controlled and monitored by a user-friendly computer-GUI system.

About ScIDre:

Scientific Instruments Dresden GmbH (ScIDre) is a technology company globally serving science and experimental research. A powerful team of engineers and scientists develops and provides equipment and technologies for the use in fundamental experiments and applied nature sciences. The offerings of ScIDre are supplemented by specialized engineering services as well as the customized production of individual parts and small series in its workshop "Campuswerkstatt".

ScIDre was founded in 2009 as a spin-off from the Leibniz Institute for Solid State and Materials Research Dresden (IFW Dresden). The know-how for a unique floating zone crystal growth furnace, which was originally developed at the IFW Dresden to operate under high gas pressures, was transferred under a license agreement as one of the first products to the emerging company. Since then, ScIDre optimized the plant design, completely reworked the control system and sells the apparatus successfully world-wide. In 2011, ScIDre was awarded the special prize for outstanding technology transfer with special development potential of the Saxon State Ministry of Science and Art (SMWK). Based on the experience in engineering of high pressure and high temperature devices, ScIDre is continuously developing new, innovative instruments for the preparation and execution of crystal growth and other scientific experiments from various areas of solid state and materials research.

About Paradim:

https://occamy.chemistry.jhu.edu/tour/paradim/index.php

Picture 1: The crystal growing plant (HKZ) for the material synthesis of complex single crystals.

Picture 1: The crystal growing plant (HKZ) for the material synthesis of complex single crystals.

Picture 2: The process chamber is located at the focal point of the upper mirror of the HKZ. Here, the crystal growth takes place at temperatures of up to 3000 °C and a gas pressure of up to 300 bar.

Picture 2: The process chamber is located at the focal point of the upper mirror of the HKZ. Here, the crystal growth takes place at temperatures of up to 3000 °C and a gas pressure of up to 300 bar.

Scientific Instruments Dresden GmbH (ScIDre)

Gutzkowstr. 30, 01069 Dresden, GERMANY

Tel. +49 351 821 131 40

Robert Schöndube (Managing director)

r.schoendube@scidre.de

Tel. + 49 351- 821 131 42

Dr. Paul Saß (Research and cooperation projects)

p.sass@scidre.de

Tel. + 49 351- 821 131 464

Press contact:

Annette Lindackers

a.lindackers@scidre.de

M +49 171 834 893 4